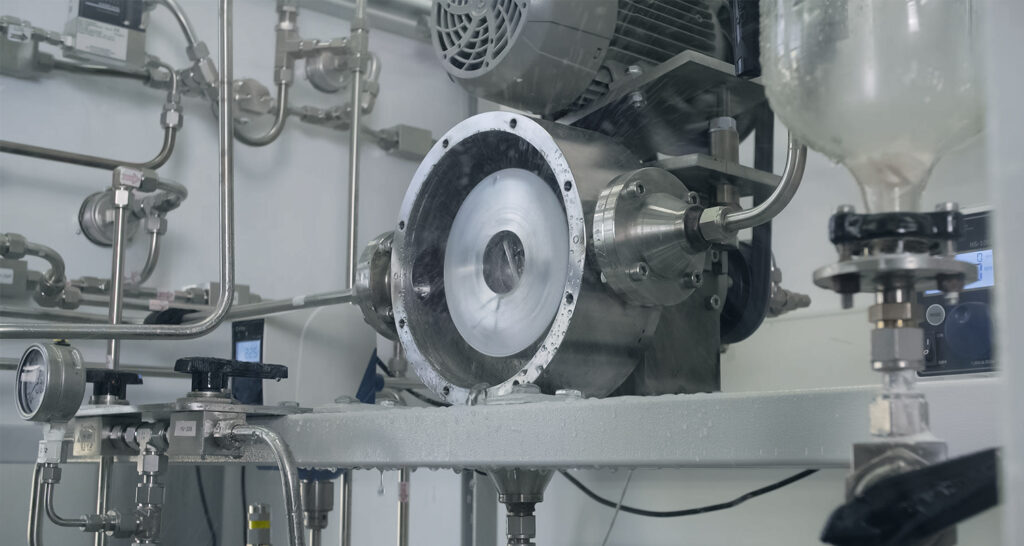

Presentation of the problem and objective of the experiment

The design of CO2 capture and utilization (CCU) systems requires the consideration of a large number of design options and operating scenarios to attain optimum and realistic design solutions of low cost. The problem is computationally very challenging, due to the need to consider multiple different materials, different process structures and operating conditions. As a result, existing algorithms for integrated process design and controllability assessment and computing practices that are based on personal computers result in suboptimal designs.

Organisations involved

| End User: Y Squared Private Company | Domain Expert: : Centre for Research and Technology Hellas | HPC Expert: Yotta Advanced Computing d.o.o.GRNET |

Short description of the experiment

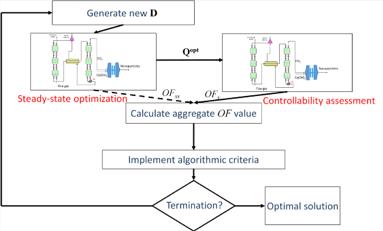

CCUPAR developed a parallel algorithm for integrated process design and controllability assessment of advanced CCU systems. The algorithm accounts simultaneously for different materials and process structures and a broad range of operating scenarios. We have demonstrated the ability of the algorithm to identify designs that reduce the capture and utilization costs compared to conventional designs, with limited computational effort. The algorithm was implemented in the design of CCU solutions for the cement and quicklime industries. Partners CERTH and Y Squared collaborated to provide consultation to the considered and other industrial sectors (e.g., power, refining etc.) on design studies that will motivate investments in CCU infrastructure. Partner YOTTA demonstrated the ability to host this type of application in their HPC system.

Outlook

Y Squared and CERTH have already integrated the capabilities of the algorithm and the process models into their consultation and research services. In parallel. the partners plan to continue upgrading the algorithm in order to include additional processes and capabilities.

Lessons learned

Y Squared gained new and useful knowledge on process design, optimization, and control, as well as the deployment of parallelized algorithms in HPC infrastructures. Y Squared learned to handle and modify the algorithm in order to meet their needs, thus it will be an important tool in their hands that will improve the quality of their services and reduce greatly the required time to acquire their results. CERTH had the chance to optimize their algorithm and test it for real, large-scale plant flue gases. Yotta expanded their network, possibly leading to new future partnerships with Y Squared, CERTH or other partners of theirs.

Expected impact

Social

Experiment CCUPAR aims to contribute to the wide deployment of CO2 capture and utilization in industry, especially to the heavy industrial emitters. The large-scale adoption of these technologies with novel and superior solvents and process designs, compared to the conventional ones, is expected to make substantial economic and environmental impact, including sustainable and eco-friendly industrial production that aligns with the future EU goals, circular economy, and the conversion of the CO2 storage problem into an opportunity to boost the economy with a high-value product, while using the captured CO2.

Business

Due to the speed up achieved through employing HPC, the company engineers managed to increase their efficiency and produce improved designs in short amount of time. The significant decrease in computation time allows Y Squared to take on more clients simultaneously and provide them with its customized and specialized services. The increased workload is expected to result in the creation of several job vacancies, as well as internship opportunities for young trainees to get exposure to chemical process design and modelling, advanced computing techniques, and HPC.

Exploitation roadmap

Y Squared is currently engaged in the design of CO2 capture and utilization processes, primarily serving as a consultant for the cement and quicklime industries. Currently, there is only a limited number of commercial capture plants installed and no utilization plants, but the demand of such plants is expected to rise significantly due to the strict CO2 regulations set by international treaties and bodies, especially for the high-emitting industries. The improved software provides Y Squared with a competitive advantage in the market and the opportunity to expand its market reach in Greece and other European countries. The simultaneous design approach developed in CCUPAR resulted in 7.5% lower cost per ton of calcium carbonate nanoparticles produced than the best, pre-project, sequential case. These are important findings because they are applicable to large-capacity industrial systems where cost improvements are essential.